Crab-shells could provide a new virucide for PPE

A material derived from waste crab-shells is being tested for use as a virucide for use on PPE and other medical devices.

North Wales-based company Pennotec (Pennog Limited) are working with experts at Bangor University to develop a unique coating which has long-lasting virus-destroying properties.

The company aims to produce coatings for PPE and medical devices, which could prevent the spread of coronavirus.

This would provide a range of innovative products that not only protect against coronavirus but would also kill any virus coming into contact with the coated materials.

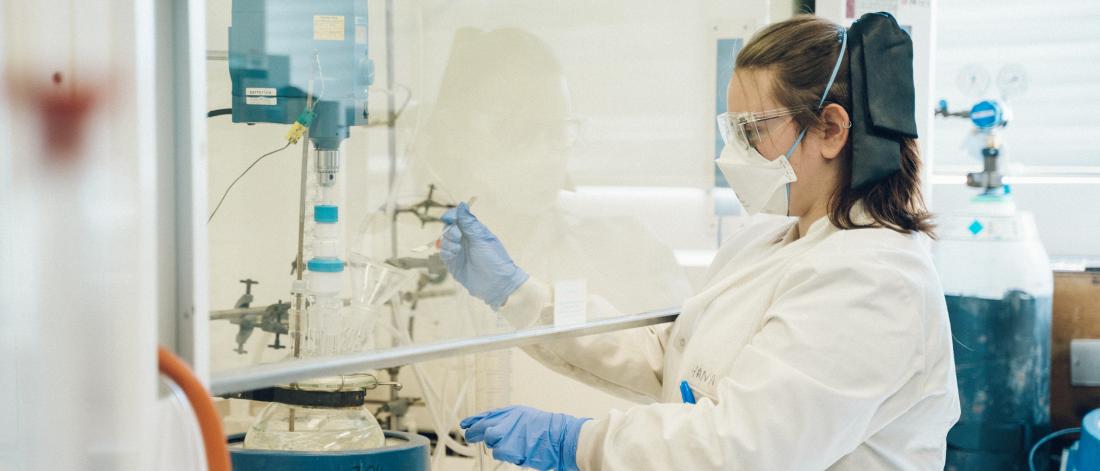

Analysis at the BioComposites Centre lab.Working with chemists at the University’s BioComposites Centre, Pennotec have modified chitosan, the chemical derived from crab shells, into naturally anti-microbial materials for the healthcare sector that will help reduce the risks of contamination from viruses.

Analysis at the BioComposites Centre lab.Working with chemists at the University’s BioComposites Centre, Pennotec have modified chitosan, the chemical derived from crab shells, into naturally anti-microbial materials for the healthcare sector that will help reduce the risks of contamination from viruses.

Once the chitosan-based coatings have been developed, their effectiveness against viruses, particularly coronaviruses, will be tested in the laboratory.

Partners Pennotec and Bangor University’s BioComposites Centre are working on the development having won funding from the heavily subscribed UK Government (Innovate UK) funding call ‘Business-led Innovation in response to global disruption’.

As a highly innovative Welsh company, Pennotec have further developed an important collaborative partnership with virology experts and clinical laboratory facilities at Cardiff University. The project, supported by the Accelerate Programme at the School of Medicine’s Clinical Innovation Accelerator, will evaluate the antiviral properties of Chitosan-treated products against COVID-19 associated coronavirus, SARS-CoV-2. Accelerate is co-funded by the European Regional Development Fund through the Welsh Government.

Dr Viacheslav Tverezovskiy explained that:

“The University’s BioComposites Centre has a track record of developing chitosan and this is underpinned by our work on smart food packaging where we have learnt how to attach antimicrobial compounds to the surface of materials. This gives us a head start in the development and is one of the reasons why our collaboration won this very competitive funding.”

J Dr Jonathan Hughes MD of Pennoteconathan Hughes, MD of Pennotec says:

Dr Jonathan Hughes MD of Pennoteconathan Hughes, MD of Pennotec says:

“We are very excited about this new application for our chitosans. Our business is focussed on developing natural products from wastes that have benefits to health, society and the environment. Medical materials are a new departure for us,” he added.

“We actually owe our existence to our partnership with Bangor University. Access to the BioComposites Centre’s facilities to work on our early product ideas enabled the development of our company and first product range. We now sell a range of chitosan formulations into water purification applications including natural pool and spa water cleaning products, which reduces the amount of chemicals needed to keep water safe and clean”

“Although there are lots of companies working to develop new anti-viral compounds, chitosan is a natural material in this arena,” explained Dr Slava Tverezovskiy of the University’s BioComposites Centre.

“We have been working with Jonathan on chitosan for many years,” he added.

The BioComposites Centre has a long track-record of working with industries on the development of new materials from natural products which can replace components or ingredients currently derived from non-renewable materials such as mineral oil.