To reduce our emissions and begin to redress the climate change balance, enzymes should be used more frequently in our industrial processes and cycles.

Bangor University’s Centre for Environmental Biotechnology (CEB) is a leading research centre focused on searching for novel enzymes and biomolecules of industrial biotechnological relevance and green growth through the use of natural resources. The Centre works to streamline and shorten the biodiversity discovery pipeline, addressing all steps, from sampling biodiversity hotspots to enzyme and bioactive compound discovery. They are a partner in a European Commission Horizon 2020 research programme, FuturEnzyme: Technologies of the Future for Low-Cost Enzymes for Environment-Friendly Products.

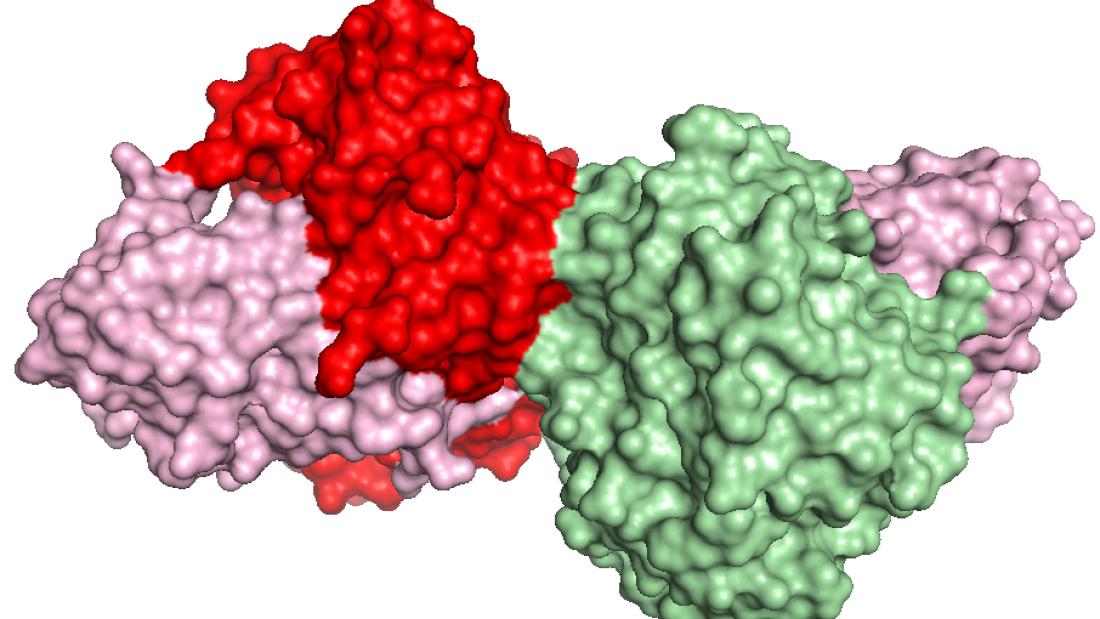

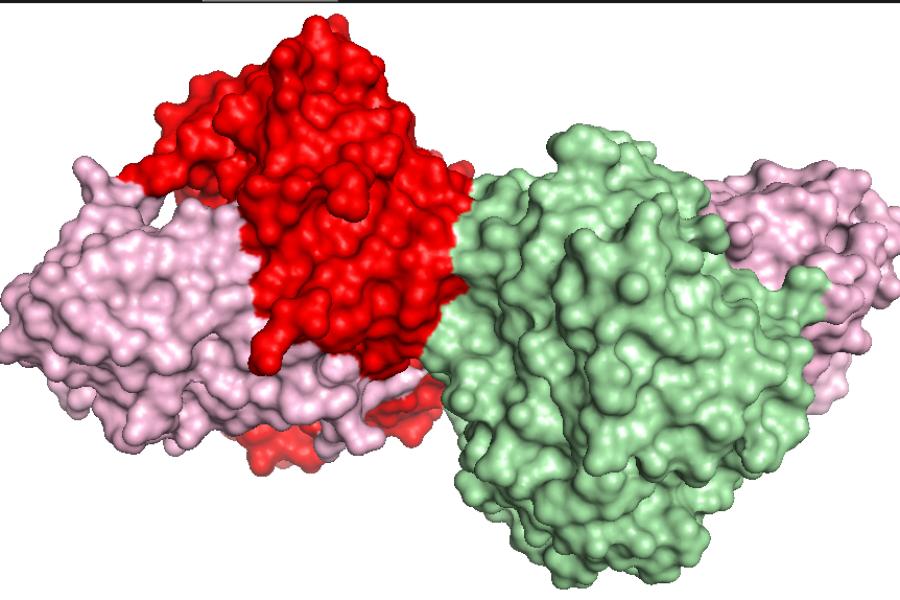

But what are enzymes and where do they come from? Enzymes are naturally occurring proteins which are essential for functioning of all living systems on our Planet.

Using enzymes in everyday products can cut waste and chemical consumption, reduce the environmental impact of industrial processes, make processing safer and lower a product or process’ carbon footprint.

One common example of their use is in laundry detergents, which we’ve all probably used, which enable us to run our washing machines at lower temperatures. They’ve been around since the 1970’s. The climate benefits of these enzymatic detergents are not to be sniffed at, estimates suggest that a drop in washing machine temperatures from 60°C to 30°C reduces the CO2 per cycle by 35%.

This is just one established use of enzymes. Enzymes can and are being adopted in our manufacturing systems in everything from construction, and the car industry, to cosmetics.

Estimates quantify that adopting enzymes in industrial processes and manufacturing could equate to a reduction in CO2 comparable to removing 16-40% of cars on the world’s roads (between 1-2.5Bt of CO2 emissions per year by 2030).

Professor Peter Golyshin at Bangor University’s Centre for Environmental Biotechnology explains:

“Our concerns regarding climate change and growing consumer demands for greener consumer products requires a search for or design of useful new enzymes. Though time-consuming and costly, the discovery or development of enzymes that we can adopt in industry and manufacture, will pay for themselves in the long term, if they move us to a more circular economy.”

“We are posed at the cusp of a new industrial revolution,” he added.

“Most industrial biotechnology processes are derived from microorganisms; these are an exceptional natural resource from which to produce safer, cheaper and greener products. To date, very few microbial enzymes have actually made it to the commercial market. One of the major bottlenecks is the laborious, costly and unreliable enzyme optimisation process required to make enzymes more stable and perform better in industrial processes.”

That is the challenge facing him and his team at CEB.

The number of enzymes which exist is so large it is practically unquantifiable. Each of the estimated 1 trillion microbial species could host a reservoir of enzymes – a mind-boggling total! So far around 270 000 enzymes have been identified, supporting 6500 different reactions, and some can be developed or have been adapted for use. Not all enzymes will have an application- as they serve to initiate vastly different reactions.

As part of the FuturEnzyme project, Prof Golyshin’s team at Bangor University are hosting the international “Thermophiles” Conference between August 29-September 2, this year.

Described as organisms which thrive in relatively high temperature environments, thermophiles can be a source of enzymes. The Conference will discuss latest news in various fields of research from ecology, phylogeny, genomics, metagenomics, molecular biology, physiology, astrobiology to biotechnology and other areas of applied microbiology.