Impact

Examples of our work with industry and applications of our research are listed below.

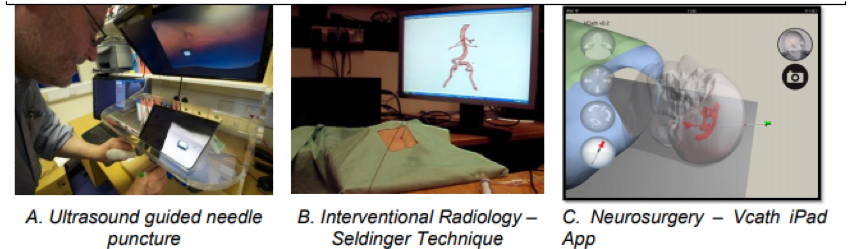

Minimally invasive procedural training for clinicians using virtual patients.

Our School has demonstrated real time 3D computer graphics technologies for training of surgeons. This is enormously beneficial to existing surgeons in the NHS and training new surgeons, allows for much higher volume training and improves the safety for patients undergoing surgery in the UK.

To do this, we developed a ‘virtual patient’ computer model, which is a sophisticated program of a human that can deliver accurate real time physiological responses to a trainee clinician using their natural senses and skills. Variations in patient anatomy and pathology, interaction between surgical tools and tissues, and human physiology such as respiration and blood flow can be modelled. The main impact of using virtual patients has been to reduce risk to real patients, reduce clinical training costs, and help clinicians maintain skills. The Bangor team developed new algorithms simulation of effects such as needle penetration into tissue of the patients and image generation. The process is used widely by the NHS today.

Enhancing of National Grid Stability via optimisation of “Dinorwig Hydro Power Station”

Our work has facilitated the creation of a variety of innovative control strategies for First Hydro, the owner of Europe’s largest pump storage plant. First hydro’s two plants are both supported by the simulation platform developed as part of our research and responsible for balancing load variation on the National. Our research produced a comprehensive plant computer model, and was used to enhance the dynamic response of the Dinorwig station; this resulted in improvement in National Grid stability and has provided competitive advantages to First hydro. The work by Bangor has led to lower energy costs to consumers around the UK and reduced the UK’s CO2 emissions. By devising new control system methods, the power station has been able to work more effectively and allows for testing of newer systems and components in hydroelectric plants.

Optical OFDM Transceiver Development and Commercialisation

Pioneering research at Bangor on the advanced communications technology termed Optical Orthogonal Frequency Division Multiplexing (OOFDM) has enabled industrial impact with global implications. Supported by 8 patent families and first-phase funding of £1.1M, the Bangor University spin-off company Smarterlight Limited, was established. Smarterlight has deployed services to several international telecommunications companies to develop advanced solutions for access optical networks and data centres. Research at Bangor has, in particular, generated extensive “know-how” for addressing difficulties associated with the implementation of highly complex, computationally intense and high-speed DSP algorithms. Using that know-how Bangor was able to make the world first experimental demonstration of a series of real-time OOFDM transceivers to enables record-high speeds of up to 30Gb/s data transmission.

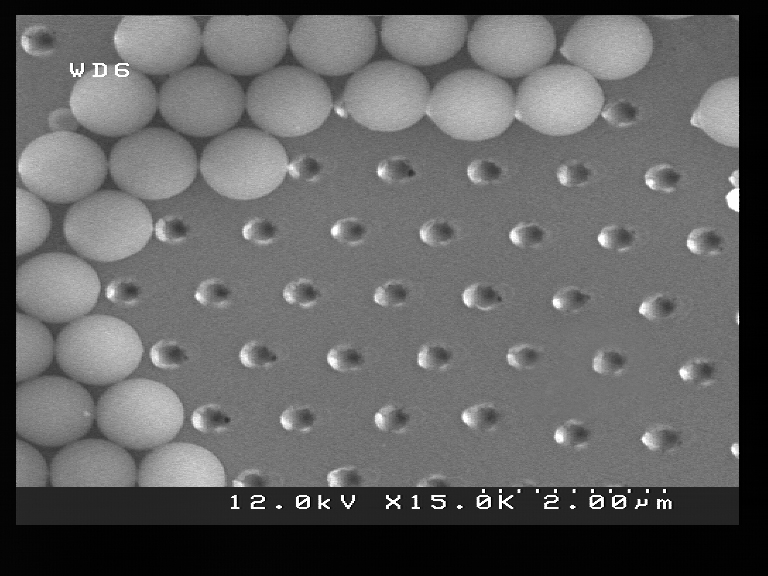

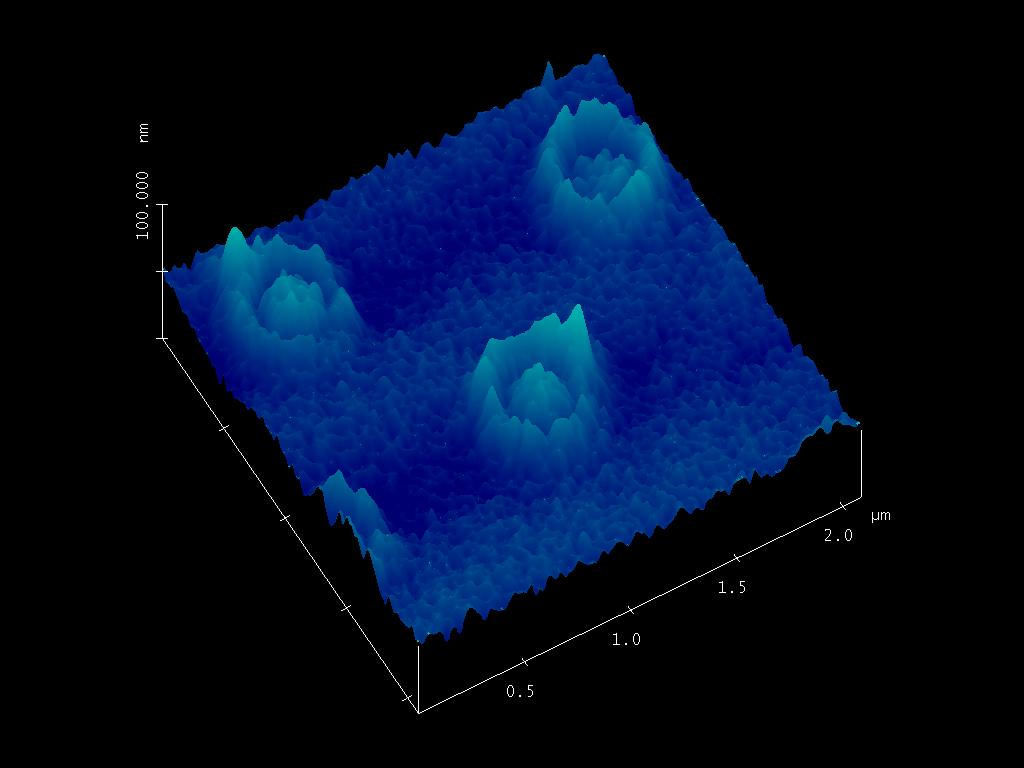

Formation of spin out company - Laser Micromachining Limited (LML)

The innovative application of laser micromachining research has been effected through Bangor’s spin-out company Laser Micromachining Ltd , LML. Laser machining can be used for making patterned structures in a variety of materials. That work has contributed directly to product development and related economic growth in sectors including medical devices, biotechnology, energy, photonics, optoelectronics, aerospace, automotive and microelectronics Bangor University gained £1.8M support from the UK government to host the UK Laser Micromachining Centre (UK-LMC) which was later spun-out from the University to form the independently business, which retains a base close to Bangor. The versatile approach adopted by LML has enabled it, to undertake many commercial contracts for more than 300 industrial customers and 60 academic institutions.